About Us

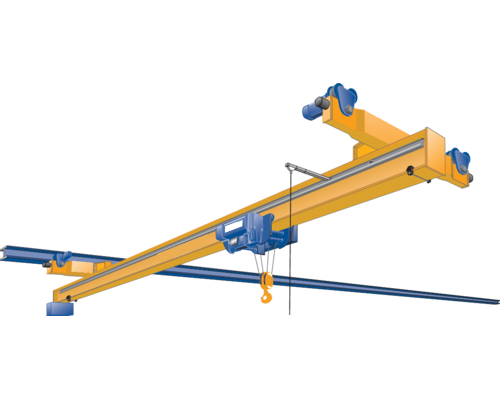

At Technomac, we are pioneers in EOT crane technology, driving innovation and precision to new heights. With a commitment to durability, efficiency, and safety, we engineer world-class cranes that optimize material handling and maximize productivity—ensuring seamless operations with minimal maintenance.